18 May 2023

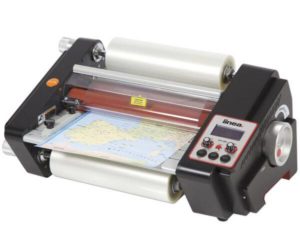

Common problems with laminating machines and how to fix them

Laminating machines are an essential piece of equipment for many businesses that require the protection and enhancement of printed documents. However, like any other machine, these laminators can sometimes encounter technical problems that can hinder their performance and cause frustration. At AfterPrint, we understand the importance of having a reliable laminating machine in your workplace, which is why we have put together this informative blog to help you troubleshoot and fix common issues that may arise with your laminating machine. In this blog, we will walk you through some of the most common problems and offer practical solutions that will get your laminator back up and running in no time. Read on to discover how you can fix your laminating machine and avoid costly downtime.

Wrinkled laminates

One of the most common problems with laminating machines is wrinkled laminates. If your laminated documents are coming out with unsightly wrinkles, it can be frustrating and can diminish the quality of your work. Wrinkled laminates can occur due to several reasons such as incorrect temperature settings, bubbles in the laminate film, or uneven pressure during the lamination process. This issue can be especially prevalent when laminating thicker materials or when using poor quality laminate film. Wrinkled laminates not only look unprofessional but can also cause damage to your documents in the long run.

How to fix wrinked laminates

To fix wrinkled laminates, first, check the temperature settings on your laminating machine. Ensure that the correct temperature is set for the thickness and type of material you are laminating. Adjust the temperature accordingly and run a test lamination to see if the wrinkles persist. If the issue persists, check for any air bubbles in the laminate film. Bubbles could be caused by uneven placement of the material or a faulty film. In such cases, you can remove the laminate and reapply it, ensuring that there are no bubbles. Alternatively, you can try to smooth out the bubbles using a plastic card or roller. Finally, if the problem persists, check the pressure settings on the laminating machine. Ensure that the pressure is evenly distributed and adjust it if necessary. If none of these solutions work, it may be time to replace your laminate film with a higher quality product.

Air bubbles in laminates

Another common problem with laminating machines is air bubbles in the laminates. Air bubbles can be frustrating as they make your laminated documents look unprofessional. They can occur due to several reasons such as uneven pressure during the lamination process, improper placement of the material, or poor quality laminate film. Air bubbles can also cause damage to your documents in the long run, especially if left unaddressed.

How to fix air bubbles in laminates

To fix air bubbles in laminates, first, ensure that the material is placed evenly on the laminating film. This will help prevent air from getting trapped between the material and the film. You can also try using a plastic card or roller to gently push out the air bubbles while the lamination is still hot. Additionally, check the pressure settings on your laminating machine to ensure that the pressure is evenly distributed. Uneven pressure can cause air bubbles to form in your laminates. If the problem persists, you may need to replace your laminate film with a higher quality product.

Clogged rollers

Clogged rollers are a common issue with roll laminators. Over time, the rollers can accumulate adhesive residue, dirt, and debris, which can cause them to become clogged. When the rollers are clogged, they may not be able to apply even pressure to the laminate film, leading to poor quality lamination. In severe cases, the rollers may become damaged or even stop working altogether. If left unaddressed, clogged rollers can lead to costly repairs or even replacement of the entire laminating machine.

How to clogged rollers

To fix clogged rollers, first, unplug the laminating machine and let it cool down completely. Then, remove the protective cover from the rollers and use a soft cloth or paper towel to wipe away any visible debris, adhesive residue, or dirt. You can also use a mild cleaning solution such as water and vinegar or isopropyl alcohol to clean the rollers. However, be sure to follow the manufacturer’s instructions on how to clean your specific laminating machine. Once you have cleaned the rollers, let them dry completely before reassembling the machine and using it again. To prevent clogged rollers in the future, be sure to clean the rollers regularly and avoid using low-quality laminate film.

Poor quality laminates

Poor quality laminates can cause a range of issues, including air bubbles, peeling, and discolouration. This can be frustrating, especially when you have spent time and money on the lamination process. Poor quality laminate film is often made with low-quality materials, resulting in a lack of durability and strength. This can lead to the film tearing or warping, especially in high-traffic areas. Additionally, poor quality laminates may not be compatible with your specific laminating machine, causing jamming or uneven lamination. To avoid these issues, it is important to invest in high-quality laminating film that is compatible with your machine. This will ensure a smooth and durable lamination process, with minimal issues or complications.

How to fix poor quality laminates

To fix poor quality laminates, start by identifying the cause of the issue. If the laminate film is torn or warped, it may be due to low quality materials. In this case, invest in higher quality laminate film that is compatible with your machine. If you are experiencing air bubbles or uneven lamination, make sure that the laminate film is loaded correctly and that the rollers are clean and functioning properly. You may also want to adjust the temperature and speed settings on your laminating machine to achieve the best results. If you continue to experience issues, consider consulting a professional or reaching out to the manufacturer for assistance. With the right materials and proper care, you can achieve high-quality laminates every time.

Conclusion

In conclusion, maintaining your laminating machine is crucial to achieving high-quality laminates and avoiding common problems. Regularly cleaning the rollers and investing in high-quality laminate film can prevent issues such as jamming, air bubbles, and discolouration. It’s important to remember to follow the manufacturer’s instructions and consult with professionals if needed. By taking care of your laminating machine, you can ensure that your documents, photos, and other materials are protected and preserved for years to come. Trust us at AfterPrint to provide you with the expertise and guidance needed for all your laminating needs.