15 February 2024

Efficiency Boost: Streamlining Your Paper Cutting Process with the Right Guillotine

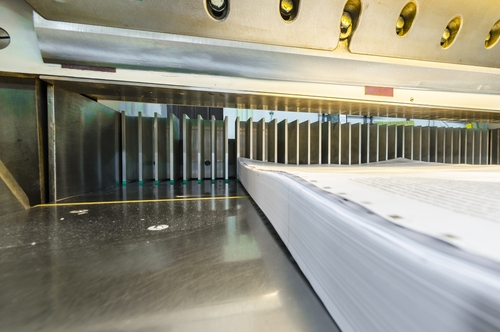

In any print production environment, the efficiency of your paper cutting process is pivotal in maintaining productivity and meeting deadlines. A well-chosen paper guillotine can make a significant difference in streamlining operations, reducing waste, and ensuring precision in every cut.

AfterPrint understands the critical role that the right guillotine plays in your workflow and is here to guide you through selecting and utilising a guillotine to maximise your operational efficiency.

Understanding Your Needs

Before selecting a guillotine, it’s essential to assess your specific needs. Consider the volume of paper you need to cut, the sizes of paper you commonly work with, and the precision required for your projects. Whether you’re running a small print shop or managing a large-scale print production facility, there’s a guillotine designed to meet your demands.

Selecting the Right Guillotine

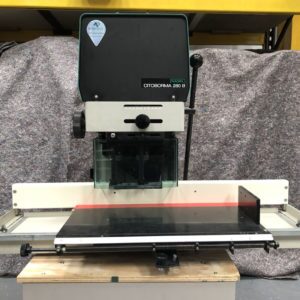

- Size and Capacity: Choose a guillotine that can handle the maximum size of paper you work with and offers a cutting capacity that meets your volume needs without compromising on speed or accuracy.

- Manual vs Electric: For smaller volumes or less frequent cutting, a manual guillotine might be sufficient. However, for higher volumes and regular use, an electric guillotine will significantly increase efficiency and reduce physical strain on operators.

- Safety Features: Modern guillotines come equipped with various safety features, such as infrared safety beams and protective guards. These features are essential for preventing accidents and ensuring the safety of your staff.

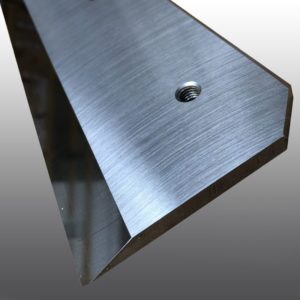

- Precision Cutting: Look for guillotines with precise backgauge adjustments and clear measurement markings. This precision is crucial for reducing waste and ensuring that each cut is exactly as required.

- Programmable Features: Advanced electric guillotines offer programmable features that can store cutting sequences for repeat jobs, further speeding up the process and ensuring consistency across batches.

Maximising Efficiency with Your Guillotine

- Regular Maintenance: Keep your guillotine in top condition with regular maintenance. A well-maintained blade and clean machine will operate more efficiently and produce cleaner cuts.

- Training Operators: Ensure that all operators are fully trained not only in the safe use of the guillotine but also in the most efficient operating procedures. Knowledgeable operators can significantly impact the speed and quality of the cutting process.

- Workflow Integration: Integrate your guillotine effectively into your overall workflow. Position it to minimise movement of materials and ensure that the output area is organised to quickly move cut paper to the next stage of production.

- Continuous Improvement: Regularly review your cutting processes and seek feedback from operators. There may be opportunities to further streamline operations or adjustments needed to maintain peak efficiency.

- Leverage Technology: Utilise the technological features of your guillotine, such as programmable cuts and digital measurements, to reduce setup times and enhance consistency across jobs.

Conclusion

The right guillotine can transform your paper cutting process, enhancing both efficiency and quality. By carefully selecting a machine that meets your specific needs and focusing on integration, maintenance, and operator training, you can achieve significant productivity gains. AfterPrint offers a wide range of guillotines and expert advice to help you make the right choice for your operations, ensuring that your paper cutting process is as streamlined and efficient as possible.