18 May 2023

The pros and cons of different types of paper binding machines

As the world becomes increasingly digital, it’s easy to forget the importance of paper documents. However, for many businesses, schools, and individuals, a hard copy still holds a valuable place in their daily operations. And that’s where paper binding machines come in. But with so many types of binding machines available, it’s difficult to know which one is the right fit for your needs. In this blog post, we’ll dive into the four most popular types of paper binding machines: wire binding, comb binding, coil binding, and thermal binding. We’ll explore the pros and cons of each binding method, so you can make an informed decision on which machine is the best fit for your needs. As experts in printing solutions, the team at AfterPrint is here to help you choose the perfect binding machine for your needs.

Wire Binding Machines

Wire binding machines are a popular choice for those who want a professional-looking document. Using a wire binding machine creates a neat and tidy look, making it perfect for presentations and proposals. It’s also easy to add or remove pages, making it an excellent option for reports that may need editing or updating. However, wire binding machines can be more expensive than other binding machines and are not suitable for binding large documents.

Pros of wire binding machines

- Professional appearance: Wire binding creates a sleek and professional look that’s perfect for business proposals, presentations, and reports. The wire binding adds a touch of sophistication, making your document stand out.

- Easy to edit: With wire binding, it’s easy to add or remove pages from your document, making it a great choice for reports or proposals that may require updates or edits.

- Durable: Wire binding is a durable option, making it an excellent choice for documents that need to withstand frequent use or handling. The wire binding holds the pages securely in place, preventing them from falling out or getting damaged.

- Variety of colours and sizes: Wire binding comes in a variety of colours and sizes, allowing you to choose the perfect match for your document. You can select a colour that complements your design or brand, making your document even more engaging.

Cons of wire binding machines

- Expensive: Wire binding machines can be more expensive than other binding machines, making them a less budget-friendly option.

- Not suitable for large documents: Wire binding is not the best choice for binding large documents, as the wire spine can only hold a limited number of pages. This can result in the need for multiple bindings or choosing a different binding option altogether.

- Time-consuming: Wire binding can be a time-consuming process, especially for larger documents. It requires punching holes in each page individually before threading the wire through and closing the loops.

Comb Binding Machines

Comb binding machines use plastic comb spines to bind documents. They are a popular choice for schools and offices due to their affordability and ease of use. The plastic combs come in various sizes and colours, making it easy to select the perfect option for your document. Comb binding machines are also suitable for binding larger documents, making them a popular choice for manuals and training materials. However, they may not be the most durable option, and the plastic combs can become brittle over time.

Pros of comb binding machines

- Affordable: Comb binding machines are affordable, making them a budget-friendly option for schools and small businesses.

- Easy to use: Comb binding machines are easy to use and require minimal training. Simply punch holes in the pages and thread them onto the comb spine.

- Suitable for large documents: Comb binding machines are suitable for binding large documents, as the plastic comb spine can hold a relatively high number of pages.

- Variety of colours and sizes: Plastic combs come in a variety of colours and sizes, allowing you to select the perfect option for your document.

- Allows for easy editing: It’s easy to add or remove pages from a comb-bound document, making it a great choice for reports or proposals that may require updates or edits.

Cons of comb binding machines

- Less durable: Plastic combs can become brittle over time, making them a less durable option than other binding methods.

- Less professional look: Comb binding can give a less professional look compared to other binding methods like wire or coil binding.

- Not suitable for heavy use: For documents that will be frequently used or handled, comb binding may not be the most durable option.

Coil Binding Machines

Coil binding machines use a plastic coil to bind documents. They are a popular choice for binding documents that need to lie flat, such as manuals, reference books, or cookbooks. Coil binding machines are also suitable for binding large documents.

Pros of coil binding machines

- Durable: Plastic coils are more durable than plastic combs, making them a better option for frequently used or handled documents.

- Lays flat: Coil binding allows documents to lay flat, making them easier to read and use.

- Variety of colours and sizes: Plastic coils come in a variety of colours and sizes, allowing you to select the perfect option for your document.

- Suitable for large documents: Coil binding machines are suitable for binding large documents, as the plastic coil spine can hold a relatively high number of pages.

- Professional look: Coil binding can give a professional look to the document, making it a great choice for proposals, presentations, and manuals.

- Allows for easy editing: It’s easy to add or remove pages from a coil-bound document, making it a great choice for reports or proposals that may require updates or edits.

- Can be opened flat: Coil binding allows the document to be opened flat, making it easier to read and use.

- Resistant to damage: Plastic coils are resistant to damage from water, grease, and other environmental factors, making them a great choice for documents that may be used in harsh environments.

Cons of coil binding machines

- Higher cost: Coil binding machines can be more expensive than other binding methods, making it less budget-friendly for some organizations.

- More time-consuming: The process of inserting the plastic coil through the document can be time-consuming, especially for larger documents.

- Less suitable for thin documents: Coil binding may not be the best option for thin documents as the plastic coil can make the spine thicker and less flexible.

- Can be difficult to bind: Coil binding can be difficult to do correctly, which can result in the coil not being inserted properly or the pages not aligning correctly.

- Limited page capacity: While suitable for larger documents, coil binding machines have a limited page capacity, which can make them less suitable for extremely large documents.

- Potential for pages to come loose: If the coil is not inserted correctly or the pages are not aligned correctly, there is a potential for the pages to come loose or fall out.

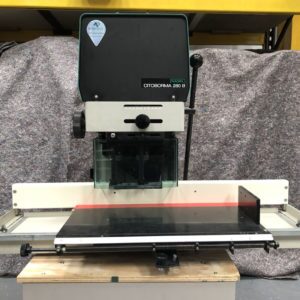

Thermal Binding Machines

Thermal binding machines use heat to bind pages together. The process involves applying a heat-activated adhesive to the spine of the document and then using the machine to heat and compress the pages together. This creates a strong and secure bond that is ideal for creating professional-looking reports, presentations, and manuals. Thermal binding machines are fast and easy to use, making them a popular choice for organizations that need to bind documents quickly. However, they are less suitable for documents that require frequent updates or editing as the binding is permanent and cannot be undone.

Pros of thermal binding machines

- Fast and efficient: Thermal binding machines are fast and efficient, making them a great choice for organizations that need to bind large volumes of documents quickly.

- Professional-looking finish: Thermal binding creates a professional-looking finish that is ideal for reports, presentations, and manuals.

- Durable binding: The heat-activated adhesive used in thermal binding creates a strong and durable bond that is resistant to wear and tear.

- Easy to use: Thermal binding machines are easy to use and require minimal training, making them a great choice for organizations with multiple users.

- No punching required: Unlike other binding methods, thermal binding machines do not require punching holes in the document, which can save time and reduce waste.

- Suitable for a variety of document sizes: Thermal binding machines can be used to bind documents of varying sizes, from small booklets to large reports and manuals.

- Cons of thermal binding machines

- Permanent binding: The binding created by thermal binding machines is permanent, which means that documents cannot be easily updated or edited without unbinding and rebinding them.

- Limited page capacity: Thermal binding machines have a limited page capacity, which means that they may not be suitable for extremely large documents.

- Higher cost: Thermal binding machines can be more expensive than other binding methods, which may make them less budget-friendly for some organizations.

- Not suitable for documents that need to lay flat: The binding created by thermal binding machines may not allow documents to lay flat, which can make them less suitable for certain types of documents.

Cons of thermal binding machines

- Permanent binding: One of the biggest drawbacks of thermal binding machines is the permanent binding they create. Once a document is bound, it cannot be easily updated or edited without unbinding and rebinding it, which can be time-consuming and expensive.

- Limited page capacity: Thermal binding machines have a limited page capacity, which means that they may not be suitable for extremely large documents. This can be a problem for organizations that need to bind reports or manuals that are several hundred pages long.

- Higher cost: Thermal binding machines can be more expensive than other binding methods, which may make them less budget-friendly for some organizations. The cost of the machine itself, as well as the cost of the binding covers, can add up quickly.

- Not suitable for documents that need to lay flat: The binding created by thermal binding machines may not allow documents to lay flat, which can make them less suitable for certain types of documents. For example, if you need to reference a document while it is open on a desk or table, the binding may cause the pages to curl or bend.

- Limited customization options: Thermal binding machines offer limited customization options when compared to other binding methods like wire binding or comb binding. While you can choose from a variety of cover colors and finishes, you cannot add additional elements like tabs or pockets to the binding.

AfterPrint’s Recommendation

At AfterPrint, we recommend considering the specific needs of your project before deciding which type of paper binding machine to use. If durability and a professional appearance are important, wire or thermal binding may be the way to go. For projects that require frequent additions or changes, comb binding may be the best option. And for thicker documents that need to lay flat when opened, coil binding is a great choice.

No matter which type of paper binding machine you choose, AfterPrint has the expertise and equipment to help you get the job done right. Contact us today to learn more about our binding services and how we can help you.