10 August 2023

Understanding The Safety Essentials of Modern Paper Guillotines

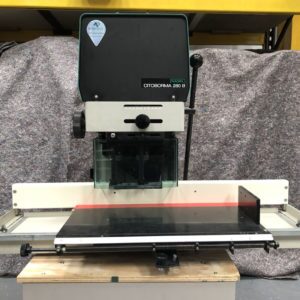

Paper guillotines have been a staple in offices, print shops, and schools for decades. These cutting machines are essential for precise and efficient paper cutting. However, as with any powerful tool, it is crucial to prioritise safety when using a paper guillotine. In this blog post, we will delve into the safety essentials of modern paper guillotines, ensuring that you are well-informed before using one.

1. Safety Features

Modern paper guillotines come equipped with various safety features to prevent accidents and injuries. These features include:

- Safety Guards: Paper guillotines are now designed with transparent safety guards that cover the cutting blade. These guards prevent direct contact with the blade while still allowing visibility of the cutting process.

- Blade Locking Mechanism: A blade locking mechanism ensures that the blade remains securely in place when not in use. This feature prevents accidental blade movement and protects users from potential harm.

- Two-Hand Operation: Many paper guillotines require two-hand operation, where both hands need to be on separate buttons or levers to activate the cutting process. This safety measure ensures that both hands are away from the cutting area, minimising the risk of accidents.

2. Proper Training

To ensure safe operation of a paper guillotine, it is crucial to provide proper training to all users. Companies like AfterPrint offer comprehensive training programs to educate users on the correct usage, maintenance, and safety procedures of paper guillotines. This training includes:

- Understanding the machine: Users should be familiar with the specific model of paper guillotine they will be using. They should know how to operate the machine, adjust settings, and perform basic maintenance tasks.

- Safety procedures: Users should be trained on the proper safety procedures to follow when using a paper guillotine. This includes wearing appropriate protective gear, keeping hands and fingers clear of the cutting area, and using the safety features of the machine correctly.

- Emergency protocols: Users should be aware of the emergency protocols in case of accidents or malfunctions. This includes knowing how to stop the machine immediately, contacting emergency services if needed, and administering first aid if necessary.

3. Regular Maintenance

Regular maintenance is essential for the safe and efficient operation of a paper guillotine. This includes:

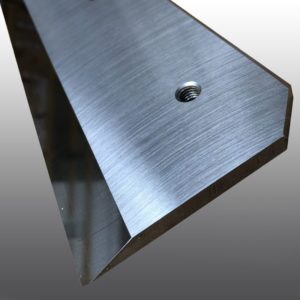

- Blade sharpening: The cutting blade of a paper guillotine should be regularly sharpened to ensure clean and precise cuts. Dull blades can lead to jagged edges and increased risk of accidents.

- Lubrication: Moving parts of the paper guillotine should be lubricated regularly to prevent friction and ensure smooth operation. This includes the blade, cutting clamp, and other mechanical components.

- Inspection: Regular inspection of the paper guillotine is important to identify any potential issues or wear and tear. This can help prevent accidents and ensure that the machine is in optimal condition.

4. Risk Assessment

Before using a paper guillotine, it is important to conduct a thorough risk assessment. This involves identifying potential hazards and taking steps to mitigate them. Some key areas to consider during a risk assessment include:

- Machine placement: Ensure that the paper guillotine is placed in a well-lit area with sufficient space for operation. It should be placed away from other machinery or equipment to prevent accidents.

- Operator training: Make sure that all operators are properly trained and familiar with the safety procedures and features of the paper guillotine.

- Emergency stop button: The paper guillotine should be equipped with an emergency stop button that can immediately halt the cutting process in case of an emergency.

- Maintenance schedule: Establish a regular maintenance schedule to ensure that the paper guillotine is always in optimal condition. This can help prevent accidents caused by worn-out or malfunctioning parts.

- Storage of materials: Properly store and handle paper and other materials to prevent accidents. Stack materials securely and ensure that they are not hanging over the edge of the cutting area.

- Cleaning and housekeeping: Keep the area around the paper guillotine clean and free from clutter. This can help prevent slips, trips, and falls.

By following these safety guidelines and best practices, users can ensure the safe and efficient operation of a paper guillotine. Companies like AfterPrint provide a range of paper guillotines and offer comprehensive training and support to help users operate these machines safely. Whether you are a small business, print shop, or a large corporation, investing in a high-quality paper guillotine from AfterPrint can greatly improve your productivity and efficiency. With their expertise and knowledge in the industry, AfterPrint can guide you in choosing the right paper guillotine for your specific needs and provide ongoing support to ensure its safe and optimal performance. Don’t compromise on safety or quality when it comes to paper cutting – trust AfterPrint for all your paper guillotine needs.