26 October 2021

What You Need To Know About Digital Die-Cutting Machines

AfterPrint is a leading manufacturer of heavy-duty printing press equipment for 50 years and one of their most renowned product lines is the digital die-cutting machines. The huge range of machinery is ideal for use by both large printing businesses and even smaller brands looking for in-house production. Indeed, there’s no match to AfterPrint’s Die Cutting Machines in terms of efficiency, durability, and high automation abilities. The machines take care of the all-around needs of the user with a simple setup that eliminates common issues associated with die-cutting machines like pressure issues, controls, and high maintenance.

How do AfterPrint’s Digital Die-cutting machines work?

AfterPrint has developed a range of diversely functional digital die-cutting machines that work on different mechanisms. The models of Graftec, Veloblade, Duplo are vacuum die cutters while the Graftcut has some highly professionally built hydraulic die cutting machines. The hydraulic die cutter works by imposing enough hydraulic force on the material to cut it while the vacuum machinery holds the item in place while a blade cuts the die. These products are a great cost-effective solution for small and large businesses to produce promotional materials on a large scale. AfterPrint’s die cutters are highly versatile and can be applied to cut plastic, PVC, PU, cardboard, rubber sheet, laminated card, Encapsulated card, and so on as long as the item has a sheet-like width.

Why choose AfterPrint’s digital die-cutting machines?

With over 50 years of rich experience in this space, the brand gives its prime focus on quality manufacturing and customer service. Consequently, AfterPrint’s long product line of digital die-cutting machines boasts of the highest quality and professional grade.

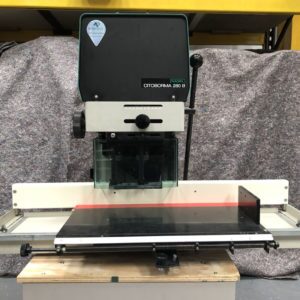

From producing outstanding packaging material for businesses to creating gift cards, business cards, invitations, laminated posters, there is no end to its application. For instance, Afterprint’s Graftec F-Mark boasts a precision camera for accurate alignment and high-precision outputs. Secondly, all the digital die-cutting machines from the AfterPrint also feature an automatic sheet feeder that provides high automation making the process easier. On the other hand, the Grafcut LC-280 from AfterPrint provides a fully automated operation with a high cut frequency of around 12,000 per minute.

AfterPrint’s long list of digital die cutters includes some of the most industry-standard professional machinery like the Duplo PFi Blade B3, Veloblade 64, Graphtec F-Mark, and so on. Some of the noteworthy features of these professional-grade machinery are fully automated vacuum feeders, exclusive software, digital flatbed, fast-cutting speed, and many other thoughtful features.

Wrapping Up

Digital die-cutting machinery is notorious for its pressure issues and software malfunctions. Hence, businesses incur a lot of loss in the long run as these types of machinery are quite expensive. In such a situation, the ideal choice is an industry-leading product that is compliant with EU standards as well as provides seamless integration for smoother control. AfterPrint with its 50 years of experience has now developed worldwide fame for its digital die-cutting machines that are known for zero software malfunctioning or hydraulic pressure issues. They ensure the manufacturing is top-notch which makes every investment worth it.